Demas AI not only finds errors, it also optimizes production decisions

Demas.AI

A New Revolution in Fabric Quality Control

These processes previously limited by human capabilities are showing significant progress in critical areas such as quality control, speed, energy savings, sustainability and cost in the new era. Artificial intelligence technologies that can be integrated into existing manual systems stand out with the aim of becoming a pioneer in industry operations as part of the digitized and increasingly valuable data-driven world.

Demas Artificial Intelligence Technology

Quality control, speed, energy savings, sustainability and cost

Demas.AI Technology

Demas.AI is revolutionizing traditional, human-driven fabric quality inspection processes with its ground breaking technology.

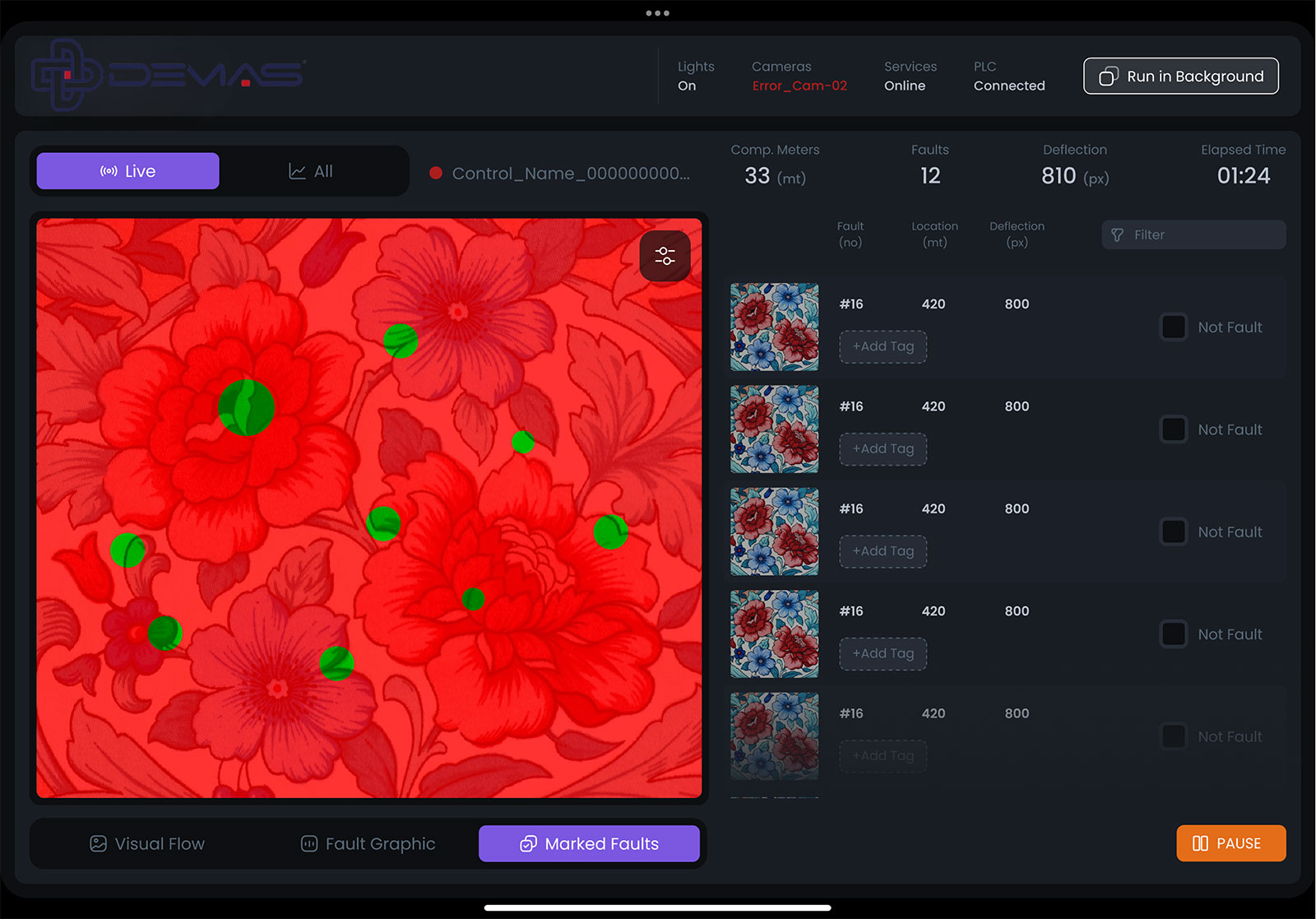

Innovative Interface

With its innovative interface, DEMAS.AI not only detects the defects during real-time streaming also simplifies the operator monitoring process. It can integrate with third-party software and generate instant reports.

AI Based Fabric Quality Control

This innovative device by Demas.AI instantly detects fabric surface defects through AI-based analysis, accelerates inspection processes and optimizes material usage for greater efficiency.

Real-time Streaming

Demas.AI's modern and innovative interface detects defects during real-time streaming, simplifying the operator monitoring process.

We catch what other miss

Plained fabrics & patterned fabrics

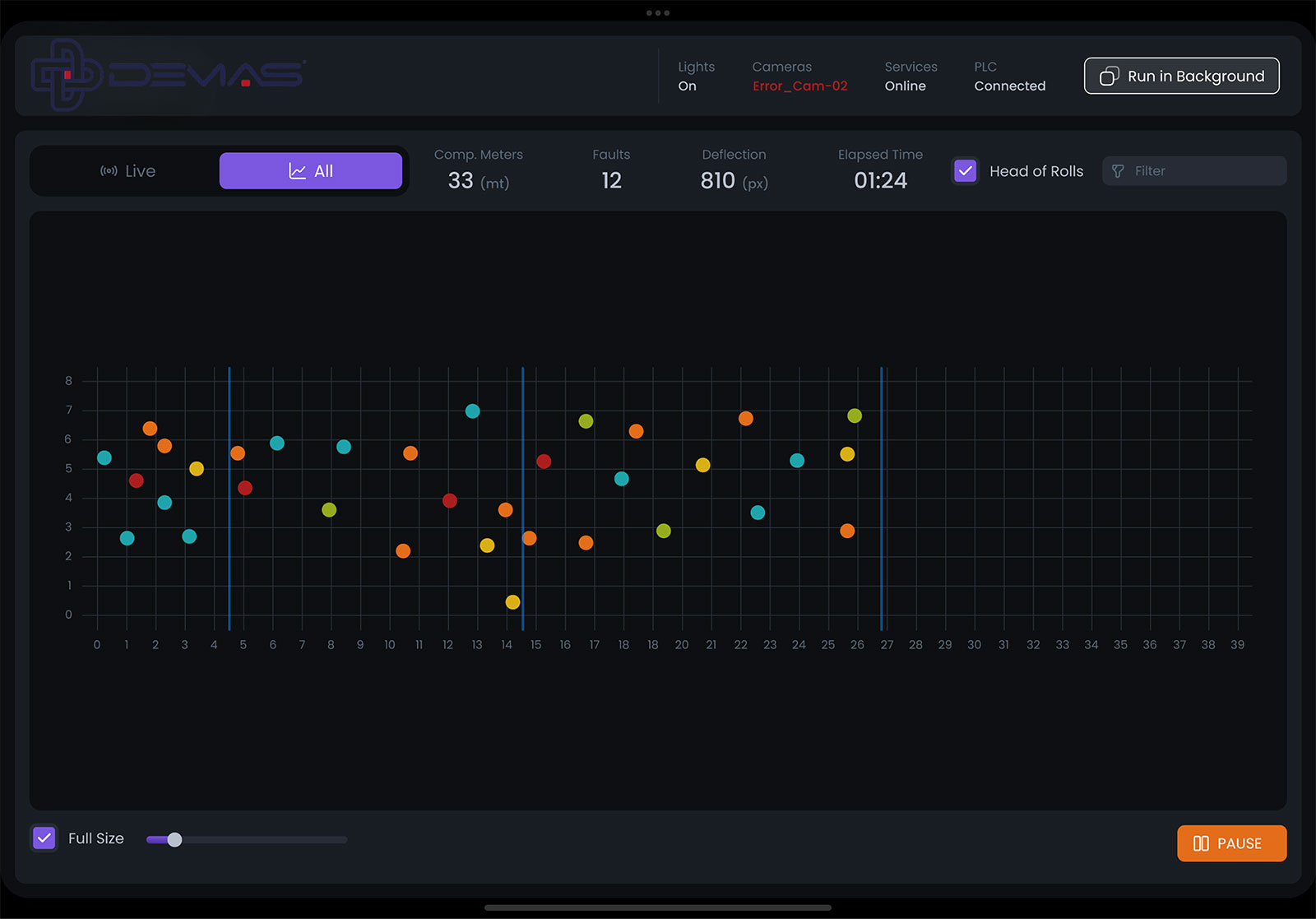

The live map displaying real-time error detections has simplified process management for operators. Additionally, the defects map is made available as a report.

simplified process management for operators

- High-resolution camera

- Thermal camera for defect detection.

- Adjustable defect sensitivity.

- Real-time defect detection and mapping method.

Key features

Smarter vision, Stronger quality

The system displays defect images and their real-time locations in front of the operator through a user-friendly interface. Detected defects are automatically classified, recorded, and visualized on an intuitive touchscreen.

State-of-the-art hardware

- Automated real-time quality control

- Seamless integration into production lines at full operating speeds

Textile Expertise

- Continuous data-driven collaboration for optimized business outcomes

- Advanced guidance from textile experts with deep industry knowledge, supported by AI

Data-driven software

- An integrated platform that centralizes quality data

- Automated data collection, analysis, and visualization

- AI powered data processing and reporting functions for enhanced efficiency

- Optimized business outcomes

- AI powered

- Real-time streaming

- Energy savings

- Sustainability

- Cost saving

- Integration 3rd party programs

Our project

Real-time Streaming & User-friendly interface

Real-time error detections

The live map displaying real-time error detections has simplified process management for operators. Additionally, the defects map is made available as a report.

Various classification and grading options

A dedicated quality defect map is generated for each roll, which can be thoroughly reviewed using the integrated album software. Demas.AI offers various classification and grading options, allowing rolls to be categorized based on the number, size, and location of defects as well as specific customer criteria.

Textile Machinery AI Technology

Demas.AI tells the story of the fabric without error.

Real-Time Image Analysis

Demas.AI monitors your production line with high-speed industrial cameras. It analyzes every frame in milliseconds, automatically detecting and flagging defects.

- High-resolution camera

- Thermal camera for defect detection.

Full Integration with the Machine

It communicates directly with PLC, sensors, and quality control systems. When an error is detected, it automatically sends a stop or flag command to the production line.

Cloud-Based Reporting

All data is securely stored on the Demas Cloud. Access error history, reports, and visuals from anywhere in the world.

Export

Export to 48+ countries

Argentina

Argentina

Belgium

Belgium

portugal

portugal

Austria

Austria

Finland

Finland

Ukraine

Ukraine

Greece

Greece

Chile

Chile

Italy

Italy

United Kingdom

United Kingdom

England

England

Sweden

Sweden

Liechtenstein

Liechtenstein

India

India

Central African Republic

Central African Republic

Serbia

Serbia

Argentina

Argentina

Belgium

Belgium

portugal

portugal

Austria

Austria

Finland

Finland

Ukraine

Ukraine

Greece

Greece

Chile

Chile

Italy

Italy

United Kingdom

United Kingdom

England

England

Sweden

Sweden

Liechtenstein

Liechtenstein

India

India

Central African Republic

Central African Republic

Serbia

Serbia

Argentina

Argentina

Belgium

Belgium

portugal

portugal

Austria

Austria

Finland

Finland

Ukraine

Ukraine

Greece

Greece

Chile

Chile

Italy

Italy

United Kingdom

United Kingdom

England

England

Sweden

Sweden

Liechtenstein

Liechtenstein

India

India

Central African Republic

Central African Republic

Serbia

Serbia

Argentina

Argentina

Belgium

Belgium

portugal

portugal

Austria

Austria

Finland

Finland

Ukraine

Ukraine

Greece

Greece

Chile

Chile

Italy

Italy

United Kingdom

United Kingdom

England

England

Sweden

Sweden

Liechtenstein

Liechtenstein

India

India

Central African Republic

Central African Republic

Serbia

Serbia

Türkçe

Türkçe English

English 简体中文

简体中文 Indonesia

Indonesia Tiếng Việt

Tiếng Việt বাংলা

বাংলা اردو

اردو हिंदी

हिंदी සිංහල

සිංහල