Traditional manufacturing processes, which rely entirely on human control are now being transformed by artificial intelligence solutions. These processes previously limited by human capabilities are showing significant progress in critical areas such as quality control, speed, energy savings, sustainability and cost in the new era. Artificial intelligence technologies that can be integrated into existing manual systems stand out with the aim of becoming a pioneer in industry operations as part of the digitized and increasingly valuable data-driven world.

We are one of the most well-established and reliable companies in Turkey, which produces textile machinery and exports it to more than 48 countries in the world.

Becoming a leading company in Turkey with an organization that closely follows and applies technologial developments, aims to act as one with its employees, customers and suppliers, has international quality standards and image, and contributes to Turkish economy.

Responding to the needs of our consumers by prioritizing customer satisfaction, providing a quality service exceeding the customer expectations by adopting the principle of continious improvement, ensuring competitive power by staying loyal to our current values, and adopting and applying modern management systems.

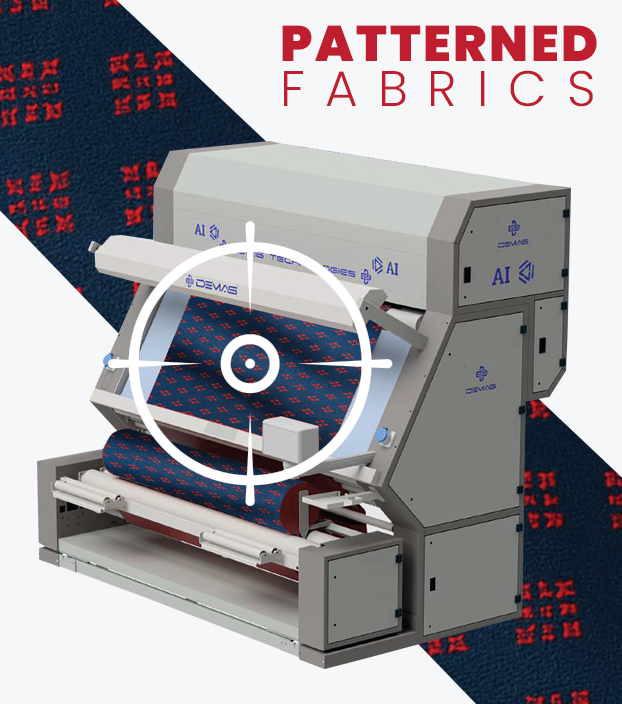

Demas.AI is revolutionizing traditional, human-driven fabric quality inspection processes with its ground breaking technology.

With its innovative interface, DEMAS.AI not only detects the defects during real-time streaming also simplifies the operator monitoring process. It can integrate with third-party software and generate instant reports.

This innovative device by Demas.AI instantly detects fabric surface defects through AI-based analysis, accelerates inspection processes and optimizes material usage for greater efficiency.

Demas.AI's modern and innovative interface detects defects during real-time streaming, simplifying the operator monitoring process.

The live map displaying real-time error detections has simplified process management for operators. Additionally, the defects map is made available as a report.